DEPENDABLE. PRECISE.

INNOVATIVE.

We Don't Just Sell Parts, We Solve Problems.

Services & Capabilities To Keep Your Company Evolving

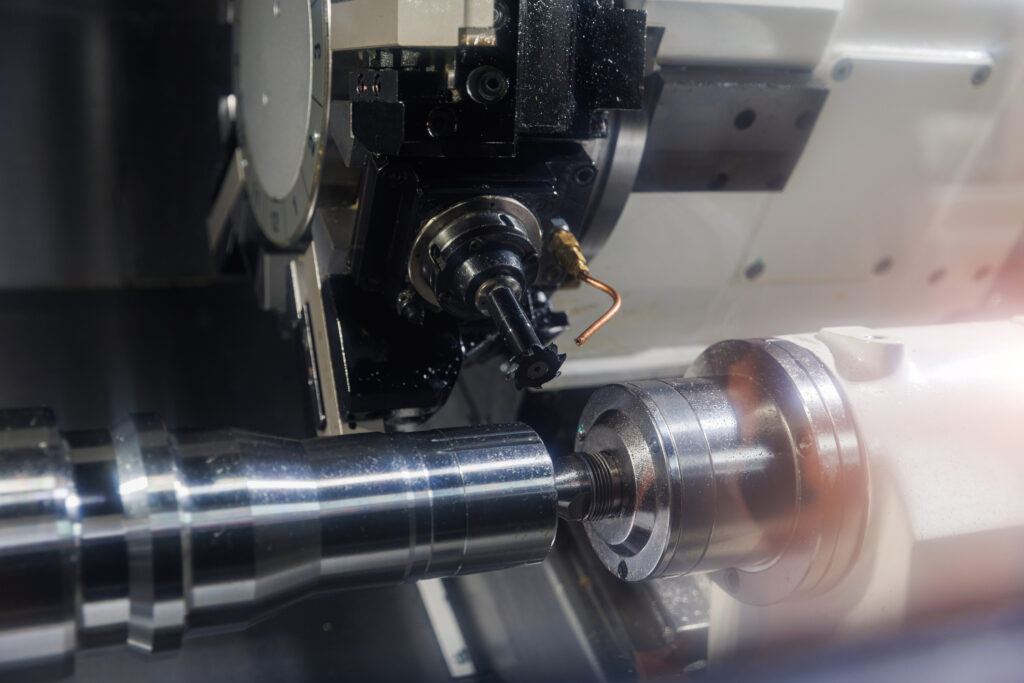

CNC Milling

CNC Turning

OEM & Supply Chain Support

The Powerful Industries We Serve

Aerospace

Cryogenics

Our CNC milling and turning services produce precise, high-quality components essential for cryogenic equipment, including heat stations, thin-walled cylinders, valve stems, and other critical compressor parts. We specialize in all aspects of cryogenic compressor technology, ensuring reliable performance in extreme low-temperature environments.

National Defense

Medical

CNC milling and turning are transforming the medical industry by enhancing precision and efficiency in manufacturing. DPI’s advanced machining ensures unmatched accuracy in medical product development, streamlining production, improving quality, and driving innovation.

Oil, Gas, and Energy

Don't see Your Industry?

From the Shop Floor: Latest Insights from DPI

From Prototype to Production: DPI’s Role in Accelerating Time-to-Market

Bringing a new product to life is rarely a straight line. The transition from early prototype to full-scale production is where many promising ideas slow down or stall entirely. Design revisions pile up. Materials behave differently than expected.

How DPI Inc. Is Pioneering Innovation on the Path to AS9100 Certification

For DPI, pursuing AS9100 isn’t just about aligning with aerospace machining standards. It’s about building a system that consistently delivers machining excellence across every industry the company supports—including aerospace, national defense, cryogenics, medical device manufacturing, oil and gas, and other high-precision fields.

Cryogenics Case Study

Eliminating Welds, Leak Paths, and Tolerance Risk in GM Cryocooler Helium Cylinders For more than thirty years, DPI has partnered with a leading cryogenics OEM manufacturing Gifford–McMahon (GM)